Lumirror® innovative PET film with high thermal conductivity

Toray succeeds in development of innovative PET film with high thermal conductivity, to contribute to improvement in energy efficiency of devices in IoT society and zero-emission society.

About product development

About product development

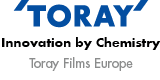

Toray Industries, Inc. (headquarters: Chuo-ku, Tokyo; President: Akihiro Nikkaku; hereinafter referred to as “Toray”) announced last month that it succeeded in development of biaxially oriented PET film with about 2.5 times higher thermal conductivity*1 of conventional products, which is the world’s highest level for PET films while retaining its original characteristics (insulation, handling ability and processability).

The use of this newly developed film in applications that require heat dissipation and thermal conduction such as insulating materials, battery materials and circuit boards is expected to improve energy use efficiency and longevity of parts.

The use of this newly developed film in applications that require heat dissipation and thermal conduction such as insulating materials, battery materials and circuit boards is expected to improve energy use efficiency and longevity of parts.

Toray completed technology establishment on a pilot scale and has started offering samples to users.

In recent years, there has been increased requirement to improve the efficiency of thermal conductivity in various industrial equipment to raise the output, improve the safety and boost productivity in the processes for the development of the IoT society and to achieve a zero-emission society.

For example, the improvement in performance from various motors, generators and cables and circuits of electronic and electrical devices leads to increased heat generation and developing countermeasures has become an issue.

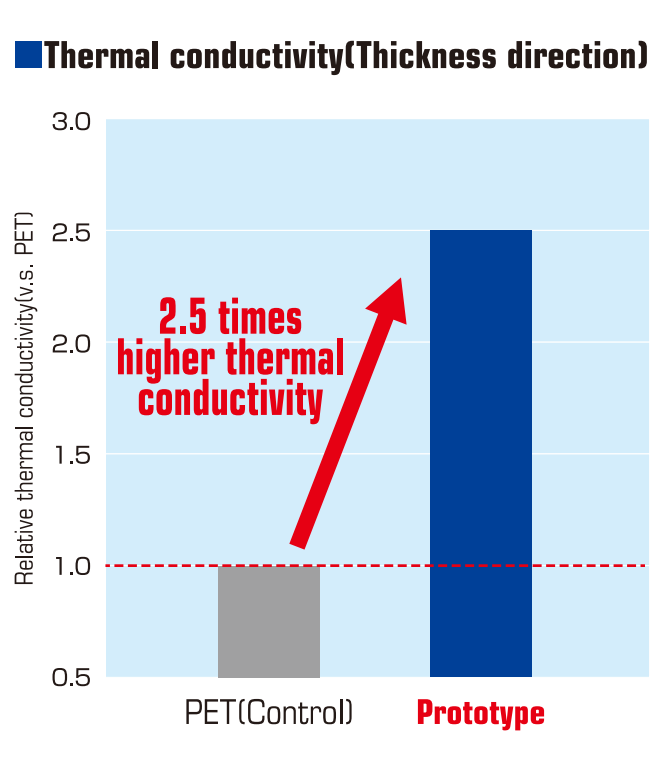

Moreover, controlling temperature rise and easing of local heat is required in battery materials to increase capacity and improve safety. As a heat countermeasure, general highly thermal conductive materials such as heat dissipation sheets and metals have low insulation and can be used in limited parts. At the same time, many cases in which PET films are used as insulating material do not have any procedures to conduct heat. For these reasons, there are growing expectations on development of PET films that combine high electrical insulation and thermal conductivity to realize control of rising temperature due to heat generation around the conductive area and ease local heat.

Our innovation

Our innovation

To improve thermal conductivity of film, it is effective to include a large amount of inorganic particles having high thermal conductivity along with insulation. However, if the interfacial adhesion between inorganic particles and PET is low and force is applied on the interface when being stretched, it peels off and many low thermal conductive voids are formed in the film. It, therefore, had been thought impossible to give high thermal conductivity to biaxially oriented PET film. In response, Toray improved the interfacial adhesion between inorganic particles and PET resin using a new particle surface treatment technology. Further, the company employed its proprietary polyester design technology to control the structure of PET in nanometer level and developed a technology to evenly reduce the stress of stretching during biaxial stretching, successfully and significantly reducing generation of voids that inhibit heat conduction.

By newly improving thermal conductivity of its biaxially oriented PET film Lumirror®, which has superior toughness, cold- and heat-resistance and chemical resistance as well as insulation, handling ability and processability, the new film is expected to improve output and safety as base film of various industrial equipment and productivity as a process film, and Toray will pursue wide-ranging development of the material.

The company announced this research achievement at nano tech 2018, hold at Tokyo Big Sight from Wednesday, February 14 to Friday, February 16, 2018.

Under the concept of “Materials have the power to fundamentally change the world”, Toray aims to contribute to the development of society and innovation of technology by continuing to create highly functional, high performance advanced materials.

Glossary

*1 thermal conductivity: physical property that shows the degree of ease of heat flow within a substance and is inherent to materials. Generally, it is expressed as amount of heat that is conveyed over one hour in a 1 meter-thick substance with an area of 1 m2 when there is 1K temperature difference between both sides. Higher the value, faster the substance passes heat.