Highlight on our Claryl® films designed for 2-ply lamination

We are constantly seeking to innovate and develop solutions that allow you to optimize your production process, improve product rendering, without neglecting quality.

Keeping this in mind, we have designed a range of Claryl® films suitable for 2-ply lamination.

Highlight on 2-ply lamination

Highlight on 2-ply lamination

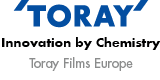

Toray Films Europe has developed 2-ply lamination solutions, allowing a simplification of laminates, as illustrated below:

Compared to traditional 3-ply lamination, it is a time saving solution that eases the manufacturing process since you remove at least one layer and a lamination step. The use of a varnish that can be applied during the printing phase simplifies the process and replaces the usual PET film for ink protection.

This alternative solution offers the same performances as the 3-ply along with a time-efficient and cost-effective process.

Indeed, 2-ply lamination enables the use of a both metallized function on the barrier side of the film and printable function on the other side of the same film.

Advantages of 2-ply lamination

Advantages of 2-ply lamination

Our Claryl® solutions

Our Claryl® solutions

Claryl® HABP

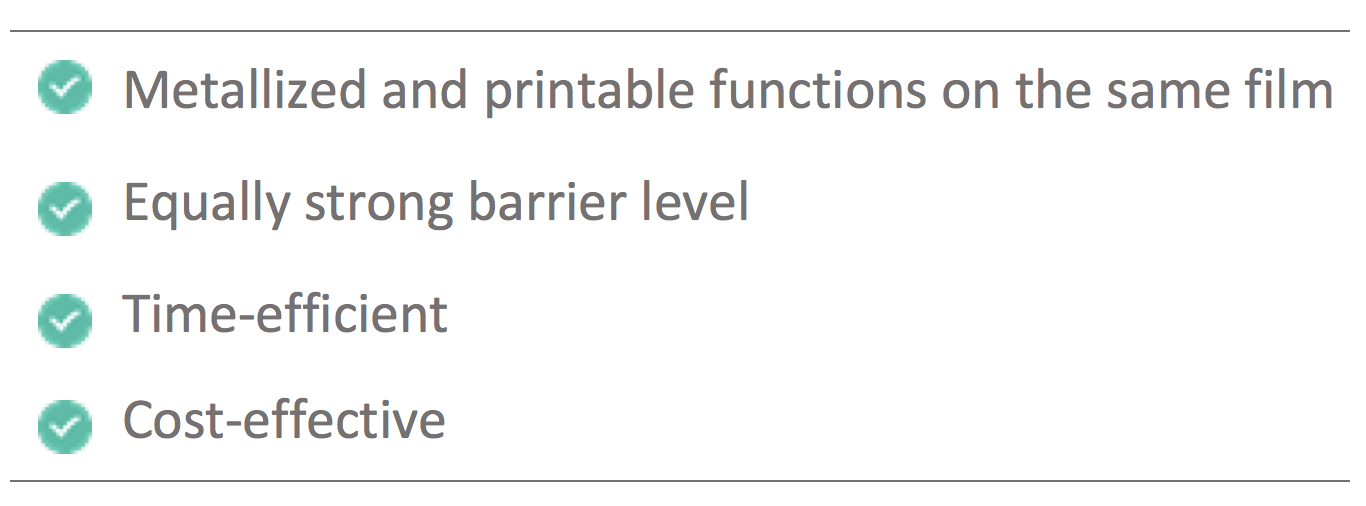

Claryl® HABP is a metallized printable PET film with enhanced metal adhesion.

The proprietary adhesion technology layer increases the metal adhesion to ensure a good lamination strength between the PE and PET film.

It offers a high gas barrier as well as high protection against natural and UV light; thus, providing an extended packaging shelf life to your product and protecting the content against lights that can alter its appearance.

It also provides high thermal stability and good machinability.

Our Claryl® HABP is printable on the external copolyester side with good ink adhesion in severe conditions. The inks are to be protected by a varnish for external application.

It is available in 12µm.

Listed below, the key properties of our innovative new film:

Application

• High end packaging laminates: with an added PE coating laminated by the customer.

Claryl® WP

Claryl® WP is a white version of Claryl® HABP. It is printable on the copolyester side and offers a high protection against natural and UV light that protects the product from oxidation.

Claryl® WP is a white version of Claryl® HABP. It is printable on the copolyester side and offers a high protection against natural and UV light that protects the product from oxidation.

The combination of white and metallized features could reduce the number of layers by up to 2 by associating in one single product both barrier and printability.

Additionally, it allows the reduction of the white ink coverage during printing process. The inks are to be protected by a varnish for external application.

It is available in 12µm, 23µm and 36µm.

Listed below, the key properties of our innovative new film:

Application

• Lidding (not only dairy)

• Frozen food decoration (both sides for shiny aspect)

• High quality performance laminates

• Stand up pouches (dry applications)