Highlight on Toray’s solution for the BOPP Thin Gauges

Innovation and sustainability have always been part of our core values. Toray aspires to offer the best quality products to its customers and is regularly aiming to reduce the environmental impact of our films. Besides our expertise in thin gauge PET films*, Toray has started to enlarge its offer on thin gauge BOPP films. Toray fully understands that across the market our customers are spending a lot of time, energy and resources to re-assess current packaging structures with a view to offering new alternatives for recyclability, bio-sourcing and mono-materials to name but a few.

Currently, BOPP metalized films can be laminated to other BOPP films to ensure the design of mono-material solutions. Secondly, our focus is to help customers reduce their potential burden due to future plastic tax implications.

Today, the role of Toray is to propose solutions by reducing the plastic quantity without compromising the performance and functionality of the packaging.

I – Toray: Expert of thin gauges BOPP

To minimize the impact of plastic, Toray Films Europe has worked on the development of thin gauges. We offer professional expertise on our products that can be as thin as 8µm, whilst at the same time maintaining ease of processing and technical performance. Having the capability of producing lower thicknesses, TFE is offering its customers films which are consistent in quality and without compromising performance.

The thickness reduction of our BOPP films allows, in fact, many advantages.

II – Performance of Toray’s thin gauges

Potential Benefits

- Less plastic helps reduce plastic tax burden

- Fewer kilos of product are required to produce the same number of impressions/units

- Option for longer reel lengths on customer rolls

- Can be used in laminates with paper giving a low %age plastic content in the finished structure

Recycling

The high expertise of Toray Films Europe allows the BOPP film to be laminated to paper in a ratio that will guarantee the minimum threshold required for the highest standards in the paper waste stream without compromising the packaging performance.

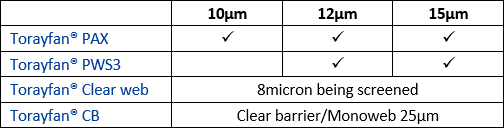

III – Our thin gauge range