Focus on the downgauging on the OPP industry at TFE

Toray aspires to offer the best quality to its customers and is regularly aiming to decrease the environmental impact of our films. Every day, Toray encourages the development of sustainable activities to help improve the global carbon footprint of our customers.

As an example, with a production yearly capacity of 22K tons, Torayfan films are predominantly produced in thinner gauges.

What are the downgauging advantages?

What are the downgauging advantages?

By being capable of producing lower thicknesses, TFE is offering to its customers films which are consistent in quality without compromising in performance.

A lower thickness results in higher film surface per reel, higher quantity per delivery and obviously, can help optimize warehouse space utilisation.

Additionally, lower thicknesses are produced in a more cost-effective way which results in a lower cost per sqm for its customers.

Which films are concerned by downgauging @ TFE?

Which films are concerned by downgauging @ TFE?

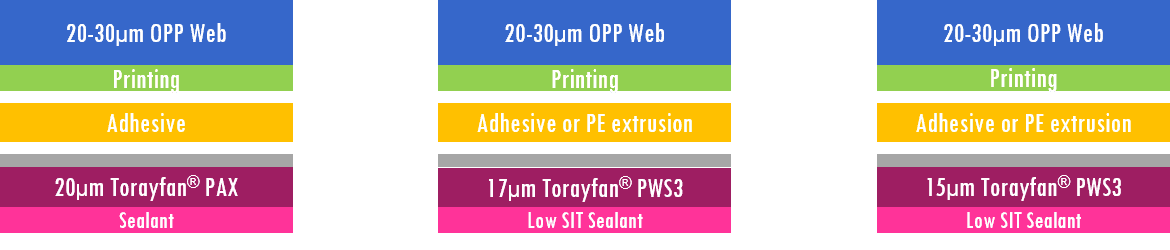

Sealable metallised films: Torayfan® PAX & PWS3

In a market predominantly dominated by 20µ, TFE offers a wide range of thickness of its sealable metallised films to be used in duplex laminates . Torayfan metalized PAX is produced in 20, 15 and 12µm while its high barrier and broad seal ranges are typically produced in 18 and 15µm.

Torayfan® Matt Films

Toray manufactures printable matt OPP in both 20µm and 15µm

Treated Films: Torayfan® F10

For specifics applications, Toray can provide the Torayfan® F10 film, a transparent corona treated film, typically in 12µm but also in 8µm