Toray’s Torayfan® PC3: a sustainable and economical solution

Toray aims to encourage initiatives and improve its products towards sustainable development. Keeping this in mind, we developed metallised barrier films allowing the shift to mono-material structures.

Mono-material packaging are preferable for recycling since their components are all based on polyolefin. At Toray, we promote alternative solutions to the aluminum foil for complex structure to switch towards polyolefin-based material such as PP.

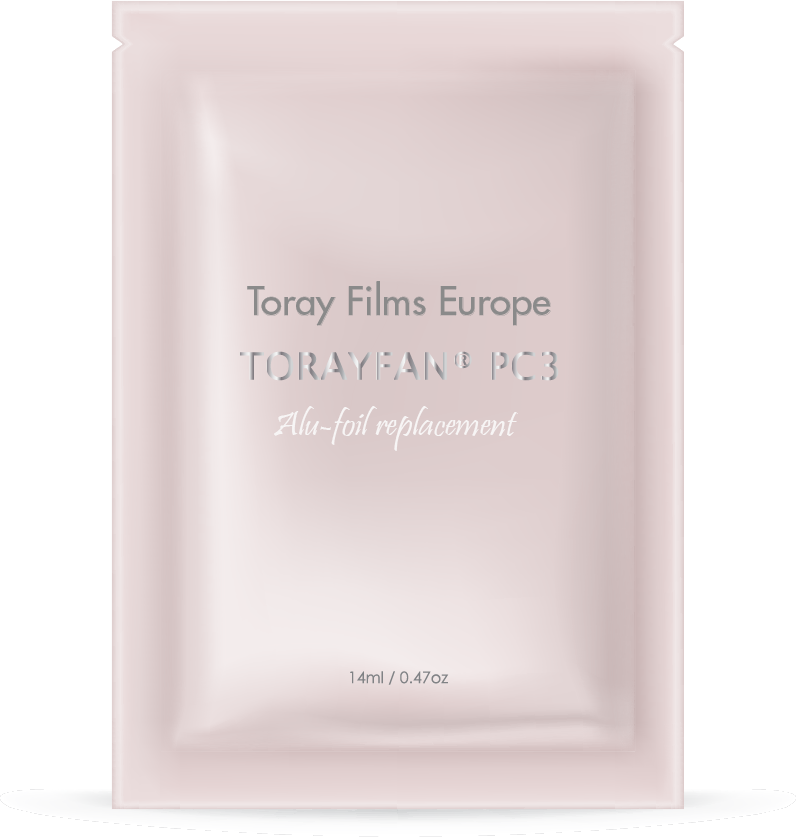

Torayfan® PC3 as a replacement to the aluminum foil

Torayfan® PC3 as a replacement to the aluminum foil

We propose a film made of polypropylene (OPP) to replace the aluminum foil usually used, thus allowing the final product to be fully recyclable.

Our Torayfan® PC3 offers excellent moisture and oxygen barrier properties, which makes it an effective alternative to aluminum foil. Its moisture barrier properties are less than 0,1 g/m2/day.

Our OPP film is suitable for adhesive and extrusion lamination thanks to its non-craze metal surface. In both cases, the film offers a great adhesion.

This film is available in 12.5µm and in 15μm, if needed to increase the rigidity of the final product. Our film offers a sustainable solution to improve the carbon footprint of the packaging, while saving money.

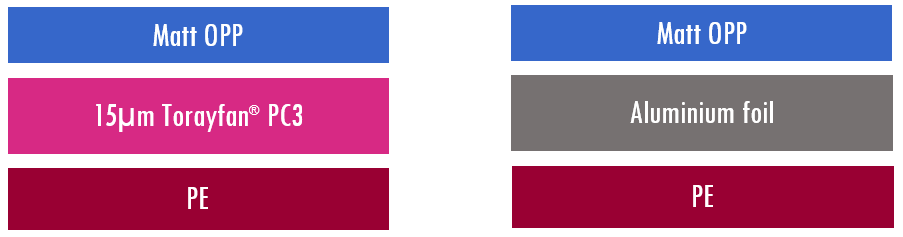

Below is an example of how our OPP film can be used versus multi-laminate structure. The first structure is fully made of polyolefin, it is therefore suitable for recycling.

Applications

Applications

The Torayfan® PC3 is particularly suitable for the packaging of:

• Powders

• Dehydrated products

• Cosmetics

• Snacks

• Bakery

• Confectionery…

Benefits

Benefits

Main properties of the Torayfan® PC3:

• 12,5 & 15 µm OPP film for alu-foil replacement in triplex

• Ultra-high moisture barrier

• Very good oxygen barrier

• Recyclable within a PO stream