For a few years now, the recycling step up compels industrial actors to modify their packaging conception. Papers & cardboards stand as pretty easily recyclable materials. However, all the chemical substances used to print on it will be mixed-up during the cardboard recycling process. For this reason, they require a specific focus.

Cardboard & Films: an efficient duo

Integrating recycled content into your production process is all to your credit. As it cannot be used on its own, a PET film guarantees a perfect chemicals and gas barrier to prevent migration. Have you found your best PET solution yet?

Key properties for the perfect match

1. The latest EU recommendations

The European Commission recently defined 3 different migration tolerance thresholds for MOAH, depending on the product fat substance level. Either used as a primary or a secondary packaging, guaranteeing a complete compliance of packaging is necessary.

2. A Functional Hydrocarbon Barrier

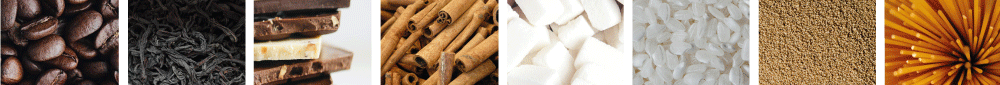

The use of a protective barrier as the best solution. Our PET films are functional barriers against MOSH & MOAH, tested by an external laboratory. We certify they comply with SVI Guideline (2015.01 – Internal Bags) requirements. More details on request.

3. Widen your range of possibilities

Used as a Primary or secondary food packaging, the MOSH MOAH barrier of our Food Safety grades operate the exact same way. It gets them suitable for lamination on cardboard and flexible packaging when used in a thin plastic complex (snacks, cereals, biscuits). Discover our Food Safety film references below.

4. As thin as possible 🌿

If you first slightly modified your production process to increase your packaging recyclability, you genuinely found how to avoid material overconsumption. By using reduced thickness film, you stuck to the exact same dynamic. Our transparent or metallised PET grades are available down to 4,5 µm, less than the usual thickness!