Focus on TAK success story: Lumirror® in-line siliconized PET films

Innovation has always been part of Toray’s identity, and is one of its most important value. With more than 10 R&D centres across the world, Toray aims, every day, at offering the best and the most innovative solutions to its customers.

The Technology R&D Centre of Toray Advanced Korea Inc. (TAK) has developed one of the newest products for the Asian market. TAK has worked on the development of several siliconized PET films, commercialized by Toray’s Lumirror® brand.

The specificities of those PET films dwell in the manufacturing process. In fact, this product is made with inline silicone coating during the extrusion process.

Benefits of siliconized films

Benefits of siliconized films

TAK’s siliconized films boasts business leading quality control and stability. With the know-hows from experiences with electronic giants such as Samsung & LG, TAK have constantly evolved to meet the highest of quality requirements. Also TAK’s siliconized films utilizes eco-friendly water base silicone layer thinner than 1µm, while still retaining its high quality.

Application of TAK siliconized films

Application of TAK siliconized films

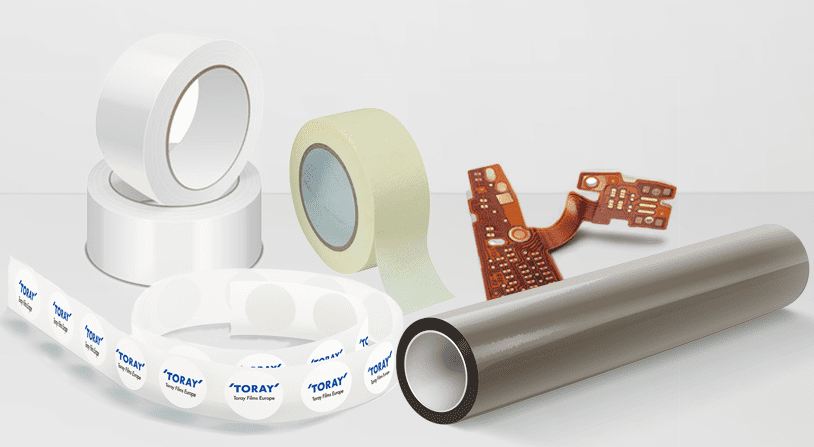

TAK siliconized films are mainly used:

- As Release Liners for Tapes, Adhesive, Labels, Paint Protection Film (PPF)

- As Carrier for Various Industrial Needs. Ex. Flexible Printed Circuit Board (FPCB)

- As Solar Window Film Liner.

- High Defect Control Required Applications. Ex. Polarizer, OCA release liner.

The films have different release properties:

Easy-release:

- XP3BR: Commodity grade. Carrier, Tape & Label

- XD5SR: Defect controlled grade. Industrial Carrier & Tape

- XD3BR: Clear Haze 2%. Window film liner

- XG7BR: Super Clear Haze Below 1%. Window film liner

- XZ31TR: Matte Both Side Release liner. Flexible FPCB Carrier

- XZ31SR: Matte Single Side Release liner. PPF Liner

Medium-Release:

- XD5YR: Water Proof/Carrier Tape.

Medium Tight-Release:

- XD5HR: Industrial carrier, OCA liner