Focus on Torayfan® and Claryl® proven performances

Pressure from legislation as well as consumer more and more drive the industry to increase green initiatives. That is why worldwide converters are moving away from solvent-based lamination and non-ecofriendly primers to more sustainable extrusion lamination process.

In this context, TORAY Films Europe and SK Functional Polymer are pleased to announce thanks to a highly fruitful collaboration, the development of high barrier laminates by extrusion lamination process with outstanding performance for flexible packaging and industrial membranes.

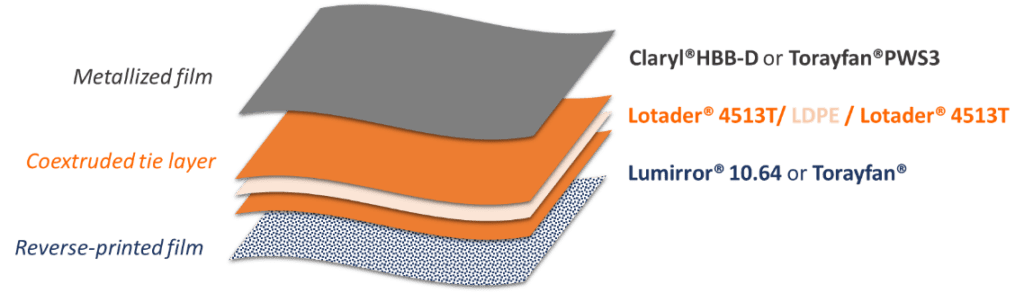

Thanks to a wide range of innovative tie layers designed by SK Functional Polymer and TORAY’s metallized films, different triplex structures have been collaboratively produced. “Barrier and adhesive performances have been assessed by TORAY and SKFP R&D excellence centers based in France”, said Dr. Océane LAMARZELLE, Market Development Manager at SK Functional Polymer.

Claryl®HBB-D and Torayfan®PWS3 high barrier BOPET and BOPP metallized films in combination with specialty ready-to-use Lotader® 4513T tie layer and reverse-printed films. “These have shown excellent results using ABA coextrusion lamination to produce triplex laminates”, said Régis LE BIHAN, Market Development Specialist at Toray Films Europe.

Benefits for converters and consumers/end-users include:

- Primer-less and solvent-free technology

- Claryl®HBB-D & Torayfan®PWS3 properties preservation during extrusion lamination process (no metal cracking, high thermal resistance, no deformation, …)

- High metal adhesion avoiding metal transfer issue at the interface metal/tie layer

- High adhesion of Lotader® 4513T on metallized and reverse printed films enabling balanced adhesion strength between layers’ interface in the triplex laminate

- Versatile adhesive properties of Lotader® 4513T terpolymer enabling converters to switch from one ink system to another

- Outstanding barrier properties to moisture and oxygen for both laminate combinations (BOPP-met/tie/ink-BOPP, BOPET-met/tie/ink-BOPET)

- Improved mechanical properties for high demanding applications (big bags, industrial laminates …)

For more information, please contact:

TORAY Films Europe at info.marketing@torayfilms.eu

SK Functional Polymer at lotader.website@sk-fp.com

___________________________________________________________________________________________________________________________________

Toray Films Europe, located in Saint-Maurice-de-Beynost (France) since 1929, belongs to the Japanese group Toray Industries. Toray Group is a market leader in engineering plastics films (PET and OPP) with 8 production sites in the world (Japan, China, Korea, Malaysia, USA and France).Toray Films Europe can rely on the strength of the group (marketing, innovation, technology…) to develop and offer customized solutions to its customers. For many years, Toray Films Europe is committed to an environmental approach and is member of CEFLEX and BOPET.

SK Functional Polymer is a newly established company headquartered in Paris, France, following the acquisition of Arkema’s Functional Polyolefins business by SK Global Chemical in June 2020. SK Functional Polymer has more than 30 years of experience in the development and supply of specialty polyolefins products from manufacturing facilities in Europe and in the USA. SK Functional Polymer markets an extensive range of specialty polyolefins that are suited to a large number of applications. SK Global Chemical is an active member of CEFLEX consortium to improve flexible packaging sustainability and recyclability.